Elevate Efficiency: Crucial Tips for Keeping Undercarriage Parts Efficiency

Elevate Efficiency: Crucial Tips for Keeping Undercarriage Parts Efficiency

Blog Article

Trick Parts: Undercarriage Parts for Heavy Equipment

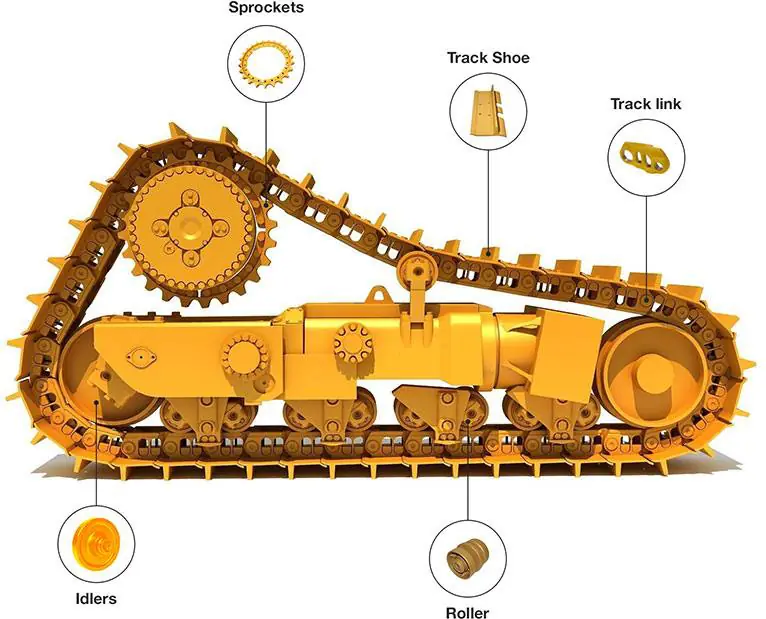

In the world of hefty equipment, the undercarriage offers as an essential foundation that makes certain the smooth procedure and longevity of the tools. Secret components such as track footwear, rollers, idlers, sprockets, and track chains play an essential duty in the performance and performance of these large machines.

Track Footwear

Track footwear play a critical function in the performance and durability of hefty equipment's undercarriage system. Track footwear come in numerous designs and products to fit different operating problems and surfaces.

The layout of track shoes is crafted to provide optimal ground call, minimizing slippage and improving the machine's capability to navigate challenging surfaces. Appropriate upkeep and normal inspection of track shoes are required to protect against early wear and ensure the undercarriage system's long life. Any kind of indicators of wear, such as unequal wear patterns or excessive damage, need to be attended to immediately to avoid costly repair work and downtime.

Rollers

Rollers are crucial parts of the undercarriage system in hefty machinery, working in combination with track shoes to assist the equipment and sustain's activity. These round steel parts are purposefully placed along the undercarriage framework and come in numerous types such as service provider rollers, track rollers, and idlers. copyright rollers assist in sustaining the weight of the equipment, while track rollers help distribute the tons and make certain smooth track shoe expression (undercarriage parts). Idlers function as a tensioning system for the track chain, maintaining appropriate track stress for ideal efficiency.

To enhance durability and effectiveness, rollers are commonly created from high-grade products like built steel, offering resistance to damage under hefty loads and rough working conditions. Appropriate lubrication is essential to lower friction between the rollers and track shoes, prolonging the life-span of both components. Normal evaluation and maintenance of rollers are vital to stop premature wear and prospective break downs, guaranteeing the continuous operation of hefty machinery.

Idlers

Idlers play a crucial duty in the undercarriage system of heavy equipment, serving as crucial parts for preserving correct track chain stress and making certain optimal maker performance. Idlers are liable for directing the track chain and sustaining the weight of the equipment. These cylindrical rollers are tactically put along the track structure to disperse see this here the machine's weight evenly, decrease vibration, and boost security throughout procedure.

Properly working idlers assist protect against early endure the track chain and various other undercarriage parts, ultimately extending the lifespan of the equipment. They also add to sustain performance by lowering rolling resistance and reducing the energy required to relocate the equipment (undercarriage parts). Normal examination and maintenance of idlers are essential to identify any kind of indications of wear, imbalance, or damage that can lead to performance issues or downtime

Gears

Playing a vital role in the undercarriage system of hefty machinery, gears are vital elements liable for moving power from the device to the track chain. Sprockets include toothed wheels or gears that harmonize with the web links of the track chain, allowing the machinery to push onward or in reverse. By understanding the value of sprockets in the undercarriage system, operators and maintenance personnel can successfully handle these elements to enhance the general efficiency and dependability of hefty machinery.

Track Chains

An essential element of the undercarriage system in heavy machinery, track chains play an essential duty in guiding the movement and supporting of the tools. Track chains are durable metal chains that connect the drive gear to the wheels or tracks of the hefty machinery. These chains are developed to endure tremendous tension, wear, and anxiety while ensuring efficient and smooth procedure of the equipment.

Track chains are composed of specific web links that are attached by pins and bushings. The style of track chains is important as it straight impacts the total efficiency and sturdiness of the heavy equipment. Proper upkeep of track chains is vital to prevent early wear, lower downtime, and extend the life-span of the devices.

Regular evaluations, lubrication, and changes are needed to maintain track chains in ideal condition. Read More Here Failure to keep track chains can cause boosted functional prices due to regular substitutes and fixings. For that reason, purchasing top quality track chains and adhering to a stringent upkeep schedule is key to taking full advantage of the performance and longevity of heavy great site equipment.

Verdict

Finally, the essential elements for heavy machinery undercarriage components consist of track shoes, rollers, idlers, sprockets, and track chains. These parts are essential for the proper functioning and operation of hefty tools, offering assistance, traction, and stability. It is crucial for drivers and maintenance workers to regularly evaluate and preserve these elements to guarantee the safety and security and efficiency of the equipment.

Key components such as track footwear, rollers, idlers, gears, and track chains play an essential role in the capability and performance of these substantial devices (undercarriage parts). Service provider rollers aid in sustaining the weight of the devices, while track rollers assist disperse the tons and ensure smooth track footwear articulation. Idlers act as a tensioning mechanism for the track chain, keeping appropriate track stress for optimum performance

Track chains are robust steel chains that connect the drive gear to the wheels or tracks of the heavy machinery.In conclusion, the key components for hefty machinery undercarriage components include track shoes, rollers, idlers, gears, and track chains.

Report this page